Ever seen rectangular, diamond or chevron black lines in the asphalt surface of a road and wondered what they are?

Inductive loop vehicle detection remains one of the most resilient and ubiquitous technologies within Intelligent Transport Systems (ITS). Despite the rapid evolution of "above-ground" sensors (such as radar, LiDAR and AI-driven video analytics), inductive loops continue to be the benchmark for reliability, accuracy and longevity in traffic management.

A common misnomer in the industry is referring to these sensors as "induction loops". While the linguistic difference is subtle, the technical distinction is significant:

Contrary to popular urban myths, standard inductive loops at traffic signals cannot be used to charge EVs! Since the 1960s, their primary role has been providing high-quality data for traffic signal control, vehicle counting, incident detection and access control.

Inductive loops are not "one size fits all". Their geometry is dictated by their specific application, whether for a high-speed motorway or a complex urban junction.

In the UK, the size and shape of detector loops in highway applications are defined in a series of national and local-authority specifications and requirements.

Some common applications in traffic systems:

Precision during installation is the primary factor for a loop to achieve a long lifespan. The process involves:

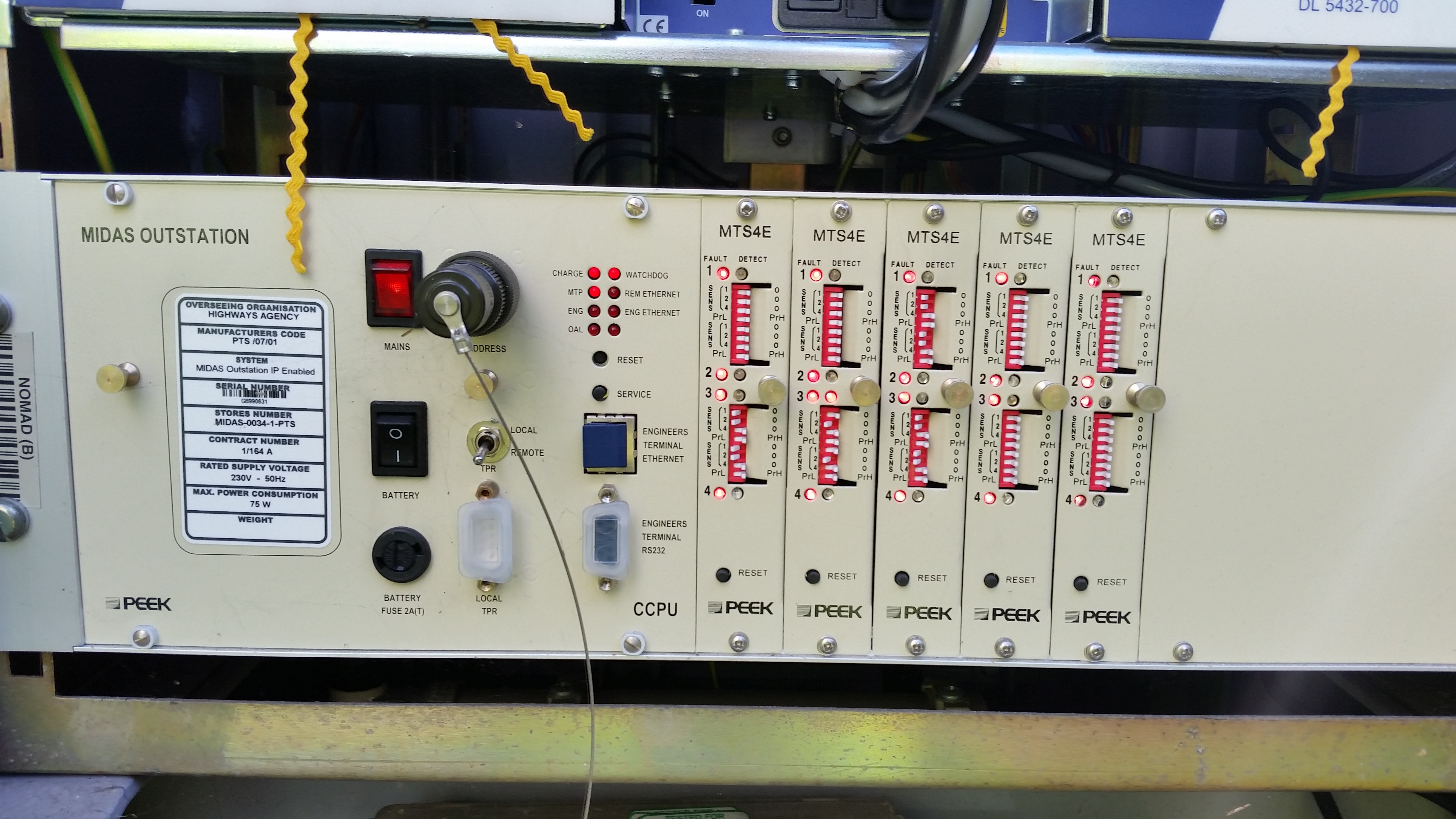

When a detector pack energises the loop, it creates an inductive field. As a metallic vehicle enters this field, it acts as a "shorted turn," decreasing the loop's inductance. The detector card senses the consequential frequency shift and triggers a "demand" to the traffic controller.

This "under-ground" approach offers a distinct advantage: environmental immunity. Unlike cameras or radar, inductive loops are unaffected by heavy rain, thick fog, snow or direct glare from the sun.

To meet National Highways and local authority requirements, loops must undergo rigorous electrical testing before and after sealing:

For MOVA (Microprocessor Optimised Vehicle Actuation) systems, the From Stop Line (FSL) distance is critical. If a loop is installed even half a metre out of position, it can degrade the efficiency of the entire junction's timing algorithm.

While robust, loops are not invincible. Their primary "enemies" are:

Inductive loops remain the "gold standard" for a reason. Their ability to provide 99.9% detection accuracy in all weather conditions makes them the essential foundation of any modern Intelligent Transport System. While we move toward a world of connected and autonomous vehicles (CAVs), the humble copper loop in the road remains our most reliable source of "ground truth" data.